While the recent film “The Martian”, starring Matt Damon, whetted the appetite of the general public for long-range human exploration, in truth, any mission to Mars is at least 20 years away. Similarly, while NASA has recently revealed its initial “Journey to Mars” plan, critics noted that it was short on detail. Nevertheless, NASA continues on its way with key parts of its exploration programme, its heavy-lift launch vehicle called SLS and its man-carrying spacecraft Orion, already under construction.

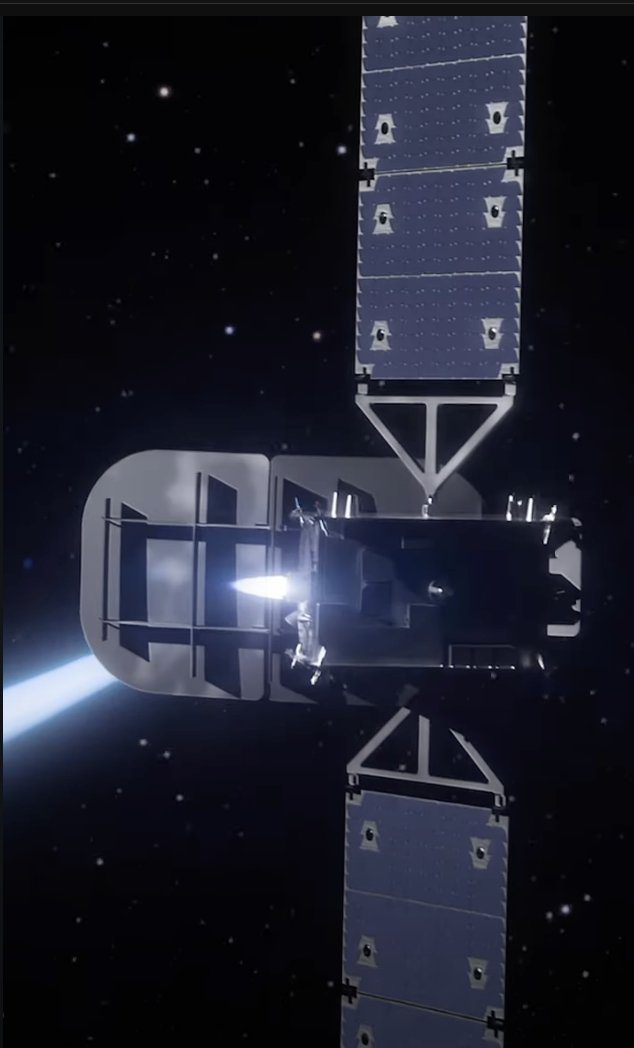

The latest artist’s images released by NASA shows that its new Space Launch System (SLS) heavy-lift rocket will be mainly “burnt orange” in colour. Previous images showed the Apollo-era Saturn V black-and-white paint work on the rocket, partly as an attempt to distance it from the still-born Project Constellation Ares V rocket design. It has now been decided that, as a weight-saving measure to the Space Shuttle, the new rocket will have its insulation unpainted for both the tank section and the adaptor.

NASA has formally announced that the SLS Block 1 rocket has passed its Critical Design Review (CDR), the first for a manned rated NASA rocket in 40 years.

It employs two 3,600,000 lb (16 MN) thrust five-segment solid rocket boosters, a four 1,670,000 lb (7.44MN) thrust RS-25 engine powered core and a Delta IV-derived Interim Cyrogenic Propulsion Stage to give it a payload to Low Earth Orbit (LEO) of 70 metric tonnes. The first flight of this SLS with an unmanned Orion space capsule on flight EM-1 is currently set for 2018.

The next planned upgrade of SLS, Block 1B, which will use the liquid oxygen (LOx)/Liquid Hydrogen powered Exploration Upper Stage (EUS), will have an LEO payload capability of 105 metric tons. This will be the version that sends a manned flight (EM-2) around the Moon probably in 2021, although this may be delayed until 2023. The Block 2 version of the SLS will have a new pair of advanced solid or liquid propellant boosters providing a minimum of 130 metric tons to LEO, although this might be stretched to above 150 metric tons depending on the choice of booster.

On the liquid side of the advanced booster competition is Dynetics, which plans to offer a booster powered by LOx and kerosene, using either two F-1B engines – a modified throttlable version of the gas-generator cycle Saturn V F-1 with a peak 1.8 million lb (8 MN) thrust – or six new 500,000lb (3.3 MN) thrust engines with a Ox?LOx? -rich staged-combustion cycle (ORSC) engine. Both engines are being developed by Aerojet Rocketdyne under the leadership of Dynetics in a continuation of a previous NASA Advanced Booster Engineering Demonstration and/or Risk Reduction (ABEDRR) contracts.

The two-F-1B booster configuration remains favoured over the six-ORSC engine per booster option, which is thought by critics to be uneconomic despite the higher efficiency of the engine cycle through the higher specific impulse compared with the F-1B. Dynetics propulsion specialist, Andrew Crocker, accepted that the small but efficient ORSC engine, whose main injector and chamber is being developed using NASA SLS ABEDRR funding, was probably more applicable for other rocket designs. However, he noted that it might still be used for SLS boosters. “The objective is to get those six engines with the same cost as the two F-1Bs,” said Crocker.

While both of the liquid fuel booster contenders are likely to have a better payload performance than the solid competitor, the Advanced Solid Booster (also being developed by Orbital ATK with the help of NASA ABEDRR funding), the final (delayed) choice of booster and engine design will be made after consideration of cost as well as pure performance. Crocker described how NASA funding had helped with the development of new thrust chambers, injectors for the ORSC engine and new gas generator and turbine blade technologies for the F-1B engine. It had also reduced the risk and cost of constructing the booster’s structure and tankage by allowing welding and construction techniques to be properly tested, including pressure proofing, thermal cycling and buckling load analysis.

Steve Creech, SLS Assistance Programme Manager at NASA, noted that the construction of the main core of the SLS rocket is under way with the NASA Michoud facility in New Orleans already producing completed tank segments. An alignment fault in the baseplate of the welding assembly had been corrected and the welding together of the tank segments could be started. Meanwhile, engine tests of repurposed Space Shuttle Main Engine/ RS-25D, are undergoing hot-fire tests at the Stennis Space Center in Mississippi, while the five-segment solid-rocket booster design to be used on the SLS Block 1 and 1B versions will be tested early next year. If all goes to plan the core stage of the SLS Block 1 should be completed by the end of 2016 ready for testing in 2017.

Orion capsule nearly through its CDR while European Service Module catches up

The Orion crew capsule is nearly through its own CDR and results have been promising enough for Lockheed Martin to begin construction even before the review is completed. Strangely, and through necessity, this will take place ahead of the CDR for its European-built service module with its delivery deadline of 29 January 2017 and quality acceptance due in November 2017.

The first circumlunar flight of the Orion and its service module in unmanned condition is set for September 2018. William (Bill) Gerstenmaier, Associate Administrator of NASA who is in charge of its Human Exploration effort, and Mike Hawes, Vice President of Lockheed Martin’s Orion programme, detailed how well the initial unmanned Exploration Fight Test-1 (EFT-1) of the prototype version of the Orion capsule (which also flew a dummy service module and the Orion Stage Adapter) on a Delta IV Heavy in December 2014 had gone.

Hawes said there had been only a minor system hiccup due to Single Event Upsets caused by Orion flying through the Van Allen radiation belts. An orange inflatable floatation device was the only significant failure on the mission. Having saluted the success, Bill Gerstenmaier paid tribute to the helpful advice given by veteran engineers who had worked on the Apollo programme.

The European Service Module (ESM) for use by Orion was born out of an arrangement whereby instead of building more ATV craft, ESA would build the ESM in lieu of the service charges it owed to NASA for use of the International Space Station (ISS). ESA is currently contracted to deliver just one European Service Module, however, there are moves afoot for ESA to barter the production of more of these craft for an extension of the ISS. Philippe Deloo, who is managing the ESM project at ESA (IAC-2015.B3.1.6), described rapid progress in the attempt to catch up with the rest of the SLS/Orion project.

Officially, the Orion Service Module consists of the US-built Crew Adaptor and the Airbus Defence and Space-built European Service Module (ESM). The ESM is 5.2m in diameter and 4m long. It carries a solar array system of 19m in span, which can generate 11.2kW of power. The ESM’s mass is 13,500kg in total. Deloo noted that ITAR technology transfer restrictions had not helped the project. Lockheed Martin, prime manufacturer of the Orion capsule, which had its own preliminary design for a service module before Europe took over the ESM, had been reduced to giving technical hints rather than hard engineering drawings during the design process.

Markus Jager, of Airbus Defence and Space, Bremen described how ESM’s main 30kN propulsion system is based on the Space Shuttle OMS-E (Orbital Manoeuvring System), which burns the hypergolic monomethyl hydrazine (MMH)/nitrogen tetroxide (N204) propellant combination, and is backed up by eight 400N Aux thrusters and 12 (+12) 220N reaction control thrusters. Deloo described how the main engine would have a higher shock and vibration environment to cope with than it would have had on the Space Shuttle. In addition, because of plume impingement effects and the bending moment effects during thrust, the spacecraft’s solar arrays are designed to be able to bend/hinge backwards and forwards when required. The eight Aux thrusters have three functions: to provide a small translational delta V velocity increment during cruise; to act as a back-up to the main OMS-E engine in case of its failure; and to provide additional thrust during a launch abort to orbit.

Deloo, while confident of achieving his tight deadlines, admitted that he would have liked more time to optimise the performance of the spacecraft. NASA’s Gerstenmaier was more reassuring, saying that while limiting overall mass was important, optimisation perfection might “have to wait for ESM 2″.

SLS can carry other stuff including 6U-cubesats

Steve Creech, of NASA, noted that SLS would have both 8.4m and 10m fairing in which a variety of unmanned payloads could be carried. In addition, for those missions using the Universal Stage Adapter on the SLS Block 1B, space would be available for items weighing up to 10 metric tons. While this would be too small for a manned lander, it might allow habitation modules to be used in cis-lunar space, or for an unmanned lunar lander to be carried.

In addition, responding to the demand for small satellite launch opportunities outside LEO, NASA has decided to build an adaptor [adaptor or adapter?] ring to carry 13 6U-cubesat class spacecraft. The 14kg mass spacecraft would be each launched in a “do no harm” power off state. While the later SLS Block 2 could carry a small 16 metric ton manned lunar module in the Universal Stage Adapter, on an “Apollo-style” flight with Orion, Creech expected that any future manned lunar lander would be much larger, flying separately on another SLS. This would be positioned in lunar orbit to rendezvous and dock with a later SLS-launched manned Orion capsule, so that astronauts could make a landing attempt.

Kathy Laurini of NASA cautioned that with NASA’s eyes set firmly on Mars, “NASA is not going to pay for the lander”. NASA Administrator Charlie Bolden had earlier noted that cis-lunar space would mainly be used as a training and proving ground for Mars missions, rather than a base for lunar surface operations, effectively dashing the hopes of ESA head, Jan Woerner, that a “lunar village” might be built as the next multi-national space project. When Charles Bolden was indirectly asked whether China would beat the USA in the race to put astronauts back on the Moon, he replied firmly: “There is no race,” before adding “Mars is our focus”.

Can SLS effectively mount a Mars landing mission? Yes – just about

While some have much grander plans for Martian colonisation, or want to mount large-scale expeditions using yet-to-be-developed nuclear powered or electromagnetic propulsion technology, there are also plans for simpler small- scale missions using existing technology.

Joe Cassady, of Aerojet Rocketdyne (IAC-2015.D2.8-A5.5.8), foresaw the use of conventional electric propulsion, with multiple 50kW modules powered by solar arrays, for at least the cargo precursor of a manned flight. Meanwhile, former Apollo moonwalking astronaut Buzz Aldrin and his team have proposed the use of cycling orbits (IAC-2015.D2.8-A5.2.6), but they admit that the key to survival for the astronauts is not to miss the cycling spacecraft in any hyperbolic rendezvous.

For a cut-to-the-bone mission, Jean Marc Solotti of the Laboratoire de’Integration due Materiou au System, described in his excellent presentation (IAC-2015.A5.2.4) how a three-astronaut mission might be mounted using known chemical propulsion technologies with just four SLS Block 2 launches. The mission would use aerocapture techniques and employ the surface habitat as crew quarters for the outbound trip. This would enable each SLS-launched flight to carry less than 50 metric tons to Mars.

While simpler transportation solutions avoid the problem of having to use nuclear power during the transportation legs of Mars missions, Kathy Laurini, Senior Advisor to the exploration programme at NASA, noted that any Martian surface operations would probably need nuclear power of some sort. They would also need more manoeuvrable pressure suits – possibly with self-sealing technologies in the event of a puncture (glove punctures have occurred in real-life space walks).

When it comes to current space suits, the experienced space-walking astronaut, Michael Lopes-Alegria, noted in an IAC plenary session how Russian spacesuits operated at higher pressures than US EMU types (5.8 psi versus 4.3 psi) and were less manoeuvrable. However, they required “less pre-breathing” and were designed to be left at a space station, while US suits needed regular servicing and maintenance back on Earth. None of the current generation of space suits is usable on the Moon or on Mars as they do not have bellows joints for moveable legs.

Other directions for the SLS rocket: it may well save the planet

Apart from its application to unmanned planetary exploration, the SLS rocket might have a role in “saving the Earth”. Nahum Melamed, of the Aerospace Corporation (IAC-2015.D2.8-A5.5.1), said that the Earth remained in danger from a strike by a major meteorite. While early warning was the main current issue, the question was also what to do if the object was on its way to strike Earth. His team’s solution was to use a ballistic strike to deflect it, and SLS was the best vehicle for that because it could handle the direct injection interception for most sizes of near-Earth meteorites (i.e. from 50m to 50km in diameter). Other smaller rockets might also be used, depending on the warning time and meteorite size.

The question is, could an SLS rocket be kept ready for such a mission? It was accepted by most that this would be expensive and even impractical (only one launch pad is available for SLS). However, having an interceptor with different adaptors for SLS as well as other launch vehicles would allow it to be ready to slot into a launch schedule. The audience regarded this as the best “ready-to-go” solution.

Comment by David Todd: During your correspondent’s studies as an astronautics student at Cranfield, he was taught that for an effective space programme to work, the public had to be kept “entertained” in between major missions. Even with a quick-to-achieve/relatively low-cost manned landing mission to Mars as suggested by Jean Marc Solotti, such an attempt could still be at least 20 years away. Given that NASA Administrator Bolden is reported to be already concerned that future political administrations may yet cancel the Mars programme, such a long wait for a Mars manned landing mission, albeit with some manned space flights into cis-lunar space in the meantime (possibly involving recovery of asteroid boulders), might cause the public and the White House to lose interest. In other words, while NASA understandably does not want its limited exploration funds to be diverted into building and operating a costly lunar village, it might be wise at least to entertain the idea of mounting some low-cost manned landings on the Moon. A cost-effective way of doing these exciting lunar revisit explorations might be for a single SLS Block 2 launch vehicle to carry the Orion capsule/service module assembly with a small two-person manned lunar module inside the SLS Launch Vehicle Stage Adapter, using a single-launch mission plan broadly similar to the Apollo missions.