Another contributor to the third plenary at the IAC 2023 Baku, Azerbaijan, was Manfred Jaumann, Head of Low Earth Orbit and Suborbital Programs in Space Systems, at Airbus Defence and Space (Airbus DS). Jaumann outlined the Starlab joint venture and the eponymous space station, which the European aerospace manufacturer is part of with US investment holding company Voyager Space – owner of Nanoracks.

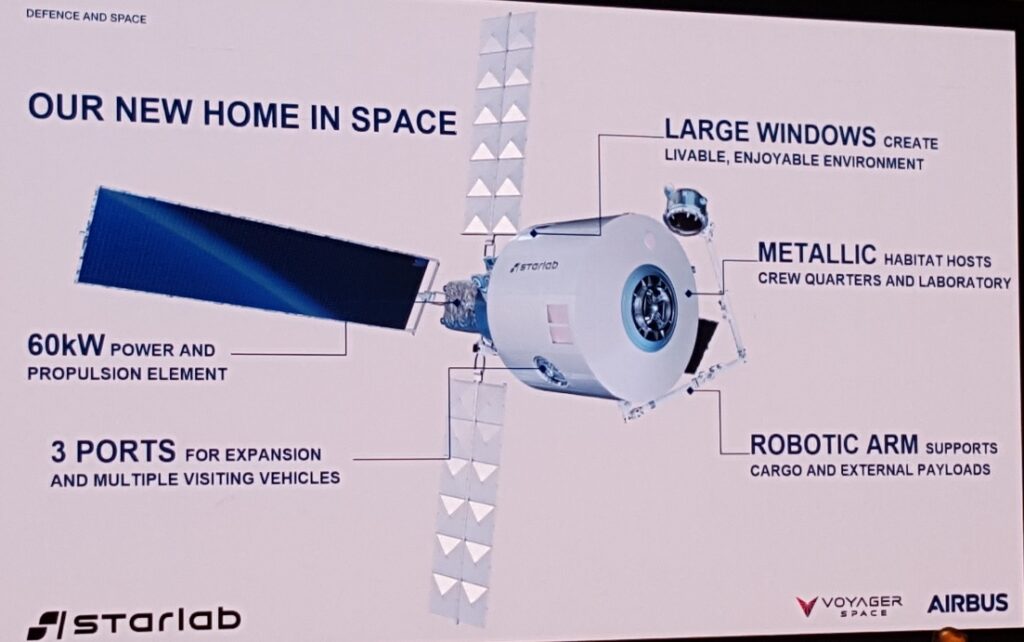

The Starlab joint venture was formed earlier this year and plans to launch a large 80 metric ton, 8 metre diameter, steel-bodied space station into orbit. This station will consist of three decks oriented around a vertical connection tube. It will be designed for a standard crew of four persons but will be able to accommodate an additional four people if required. Three airlocks will enable docking/expansion as well as the possibility to host external payloads, which could be maintained by those onboard venturing outside the station (MW comment: Manfred stressed that spacesuits would be provided).

An Airbus slide showing key points about the Starlab space station. Courtesy: Matthew Wilson

Jaumann pointed out an interesting element of the construction process: owing to its planned size and steel construction material, Airbus is looking to build the station in a shipyard and not in a cleanroom. Four manufacturers were bidding for the contract but Jaumann expected integration work to be conducted at Airbus facilities in Bremen, Germany. This unusual manufacturing method would enable the station to be built with 2.2 cm thick walls, an important factor in contributing to its 30-year design life.

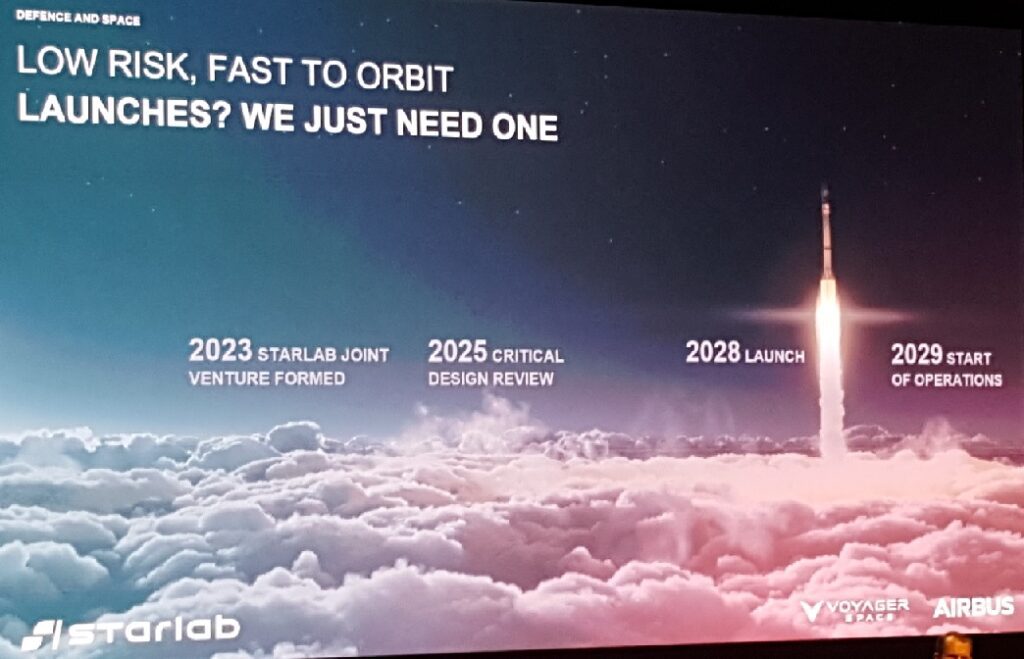

A slide showing the roadmap towards Starlab operations. Courtesy: Matthew Wilson

The intrigue didn’t end there. The sheer size of Starlab will necessitate a single launch solution currently planned for 2028. Further questioning on this matter led to the revelation that this launch contract had already been signed but was unlikely to be publicly announced before next spring (MW comment: in order to launch Starlab, Airbus will need to find a super heavy-lift launch vehicle, probably a Starship). Coming to accept this high level of risk was a learning experience for Airbus DS, according to Jaumann, who emphasised how much the company was learning from newspace players like its venture partner.

Airbus DS has not been completely converted, however. Quite prudently, long-lead parts for a second Starlab were also being procured, in case the first unit did not make it all the way to LEO.

Support for Life Support

Something that came across during the talk by Jaumann, and in later questioning, was the Airbus DS view of a potential new product line, Life Support Systems. He had previously stated that Starlab was intended to be a closed-loop system, following the example set by experience of the ISS. This would require “carbon scrubbers” to process the carbon dioxide generated by those on-board.

Airbus Group has experience with these products having developed similar technology for terrestrial industry to take emitted carbon and convert it into fertiliser, alongside the development of similar products to equip French Navy submarines. It appears Airbus DS may be eyeing up a potential new product line for the in-space market.

Comment by David Todd: While Starlab’s future looks set, we at Seradata especially like the single launch and minimal construction needed by the station. Other competitors in the race to build LEO space stations are looking shakier. After rumours that the Orbital Reef space station plan was to be axed, the Blue Origin/Sierra Space Orbital Reef team had to reassure the public that it was actively designing and testing several deliverables to NASA for the NASA CLD Phase 1 contract. However, it is understood that another runner is about to remove itself from the race, with the news that Northrop Grumman’s plan to build a Cygnus-craft-based space station is probably over.